Greencore + Bakkavor: An Engineering Turning Point for UK Food Manufacturing

When I saw that Greencore and Bakkavor were joining forces in a £1.2 billion deal a few months ago, my first thought wasn’t about sandwiches or ready meals. It was about engineering.

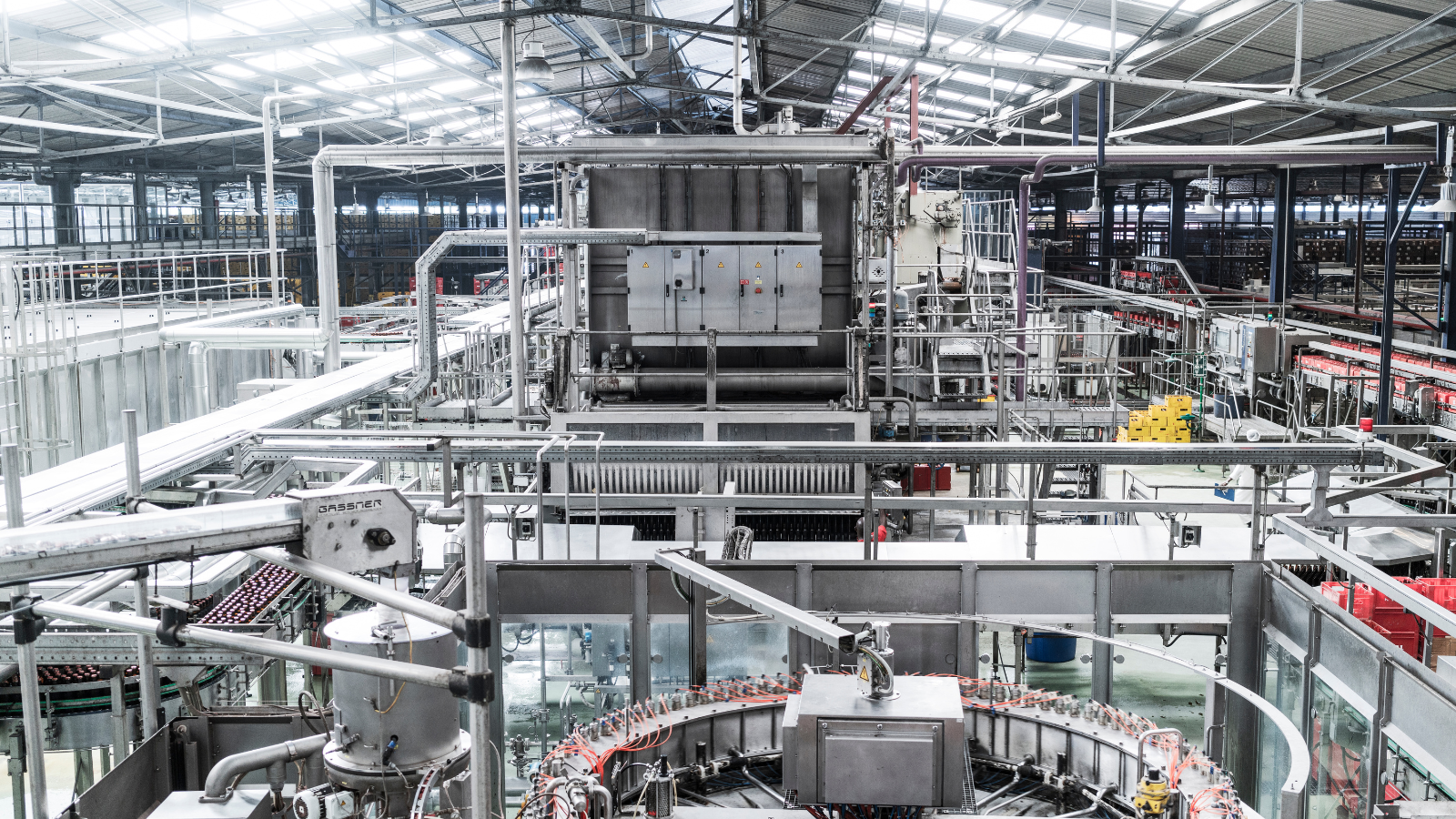

Behind every wrap, salad, or lasagne, the companies production is a complex network of machinery, automation, refrigeration systems, process lines, and data platforms. And now, with combined revenues of around £4 billion, this new food manufacturing giant may possess the scale to completely change how engineering operates in our sector.

Why This Matters for Engineers

I doubt that the merger will just be a corporate shuffle. Will it be an opportunity to standardise, optimise, and innovate across more than 40 production sites? We could then see:

Shared best practice — proven process designs in one factory can be rolled out group-wide.

Bigger capital budgets — more room for investment in automation, robotics, and smarter process control.

Data integration — combining maintenance and production data from both companies could unlock predictive analytics at scale.

It makes me consider the doors that could now open from an engineering perspective. From the exposure to cutting-edge kit and bigger, more complex projects, the future looks really positive.

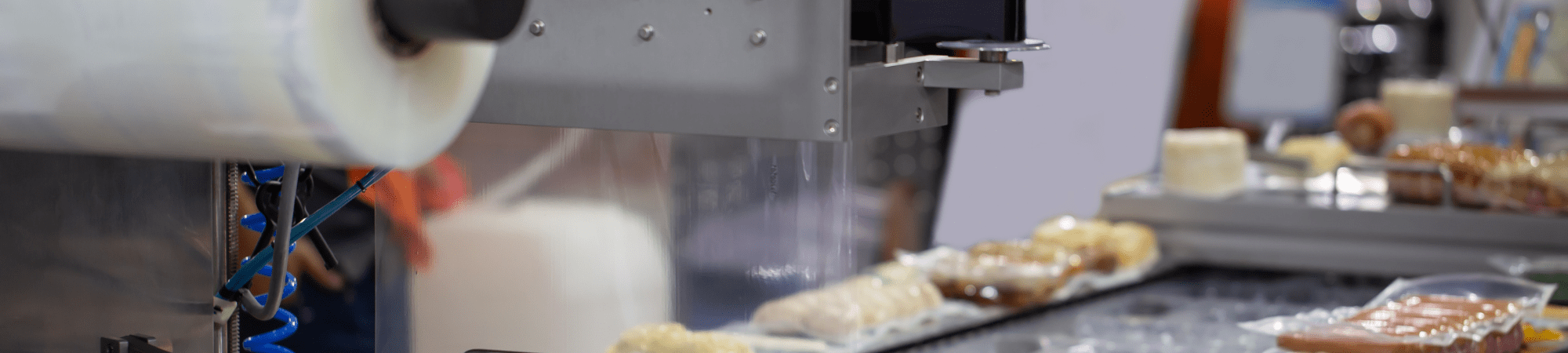

Automation & Process Innovation

Greencore has long been strong in high-volume sandwich and food-to-go assembly lines, while Bakkavor specialises in ready-meal and pizza production, both highly automated, but in very different ways. Could merging these engineering philosophies open the door to:

Modular line designs that are faster to build and adapt to new products?

More advanced packaging automation, from robotic pick-and-place to on-demand printing?

Integrated quality control systems using vision inspection and real-time data?

We could see a real leap in food manufacturing productivity.

Engineering Efficiencies = Synergy Savings

The companies are talking about £70-80 million a year in cost synergies.

From an engineering standpoint, this could mean:

Consolidated spare parts and supplier contracts.

Reduced downtime through unified maintenance strategies.

Shared engineering resource pools for specialist projects.

It’s not glamorous, but these operational gains often make the biggest difference to margins.

The People Factor

While unions are understandably concerned about job losses, engineering teams might actually see increased demand, especially for skills in automation, controls, and reliability engineering. However, it raises the question regarding balancing efficiency targets with the need to retain deep process knowledge, which only experienced site engineers hold.

The CMA will still review the deal, but from an engineering perspective, I wonder, is this a chance to align technology, process design, and maintenance philosophy across an enormous network? The possibilities are endless.

This merger could be remembered for not just creating a food giant, but for creating one of the most advanced engineering operations in the chilled-food world.